Selecting Head Protection for Construction Workers

Michael Bottlang, PhD,

Director, Legacy Biomechanics Laboratory

Legacy Research Institute, Portland, OR

Construction has the highest number of fatal and non-fatal work-related traumatic brain injuries (TBI). Non-fatal TBIs are life-altering events, whereby 43% of patients treated for TBI did not attend ordinary work for five years after injury.[1] Helmets are the single most effective tool for prevention of head injury. Over the past decade, an unprecedented variety of helmets has been introduced, differing in style, price point, compliance with standards, and manufacturer’s claims of improved protection. To develop a guideline for selection of head protection, the Occupation Safety and Health Administration (OSHA) tasked the Center for Construction Research and Training (CPWR) to form a panel of experts from academia, labor, government, and industry. In April of 2024, CPWR released the resulting guidance document, which can be downloaded at https://www.cpwr.com/wp-content/uploads/FS-Selecting_Head_Protection.pdf. This guidance document clarified that helmet performance is not based on a particular helmet style (e.g., hardhat versus climbing-style safety helmet). Rather, helmet performance is indicated by the Type I / Type II certification based on US standard Z89.1. Type I certified helmets are only tested for impacts to the helmet crown, while Type II helmets provide additional protection from front, side and rear impacts. This article summarizes guidance regarding the proper selection of Type I/II helmets, helmet retention, and most recent innovations for brain protection.

TYPE I vs. TYPE II CERTIFIED HELMETS

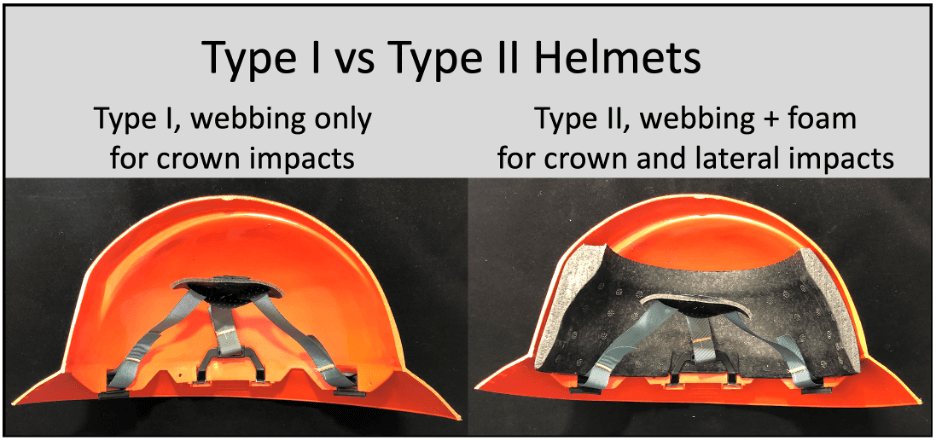

The Type I/II classification of US ANSI standard Z89.1 assesses the protection from skull fracture caused by straight impacts to the head. The strap suspension of traditional helmets is a directional design (Figure 1). It is designed to absorb crown impacts, but it was found “practically useless against side, front and rear impacts” in a 1987 helmet test study.[2] The authors of that study properly concluded that a redesign is necessary, since the majority of impacts are lateral while only 15% of impact occur to the helmet crown. The US ANSI standard Z89.1 properly recognized this shortcoming and added a Type II designation, whereby Type II certified helmets are also tested for their ability to absorb front, side, and rear impacts. A recent publication document that most helmets from leading brands still only delivered Type I “crown only” protection. This shortcoming was noted for hardhat style helmets as well as for “climbing-style” safety helmet. Many safety helmets employ a foam liner in addition or in place of a strap suspension. But this liner might be too thin or might not extend far enough to the sides to pass Type II testing, as shown in a recent publication titled “Climbing style safety helmets do not improve impact protection over type II hard hats”.[3] Selecting an ANSI Type II helmet, regardless of style, is therefore important to provide the best protection from skull fractures.

Fig. 1: The strap suspension of a Type I helmet is optimized for crown impacts, but not lateral impacts. Adding a foam liner can provide Type II protection from lateral impacts.

HELMET RETENTION

A helmet can only provide protection if it stays on the head during a fall. Chin straps can readily prevent a helmet from falling off the head. The US standard ANSI Z89.1 does not require chin straps but requires retention testing of chins straps if they are supplied with the helmet. In contrast, the European standard EN 12492, titled “Helmets for Mountaineers” requires chin straps. This standard is often used for “climbing style” safety helmets, since it requires chins straps as well as lateral impact testing. For best head protection, helmets with chin straps should be selected. While an EN 12492 certification will ensure the presence of a chin strap, this standard is no substitute for meeting ANSI Z89.1 Type II performance.

BRAIN PROTECTION

Brain protection has been the blind-spot in helmet design. A September 2023 article in Occupational Health & Safety, titled “Addressing an Overlooked Danger”, stated that current helmet standard must be updated to account for rotational motion, which is the key cause of concussions on construction jobsites. There are two different types of head injuries, namely skull fracture and brain injury. Fracture of the hard but brittle skull is caused by a straight impact,[4] similar to the straight impact one would induce to crack a brittle eggshell. A rigid helmet shell combined with an impact-absorbing liner or suspension greatly reduces the skull fracture risk by decreasing the force of a straight impact to the skull.

Conversely, brain injury is mainly caused by head rotation in response to an impact.[5] Head impacts typically cause a short but forceful head spin that twists the brain and shears the soft brain tissue. Similar to severing nerves of the spinal cord, shearing of brain tissue causes irreversible damage that may lead to life-long suffering with staggering financial implications. Brain injuries can range from a mild concussion to severe traumatic brain injuries, whereby the cost associated with a single work-related traumatic brain injury typically exceeds $1 million.[6] This staggering human and financial cost of brain injury is often caused by rather simple and frequent events. Over 60% of work-related brain injuries are caused by simple slips, trips, and same level falls.[7] Most interestingly, over 90% of such brain injuries occur in absence of a skull fracture,[4] which further confirms that the soft brain is injured by a distinctly different mechanism than the hard skull. However, this critical vulnerability of brain to rotational forces is neither considered in standardized helmet tests nor accounted for in traditional helmet designs.

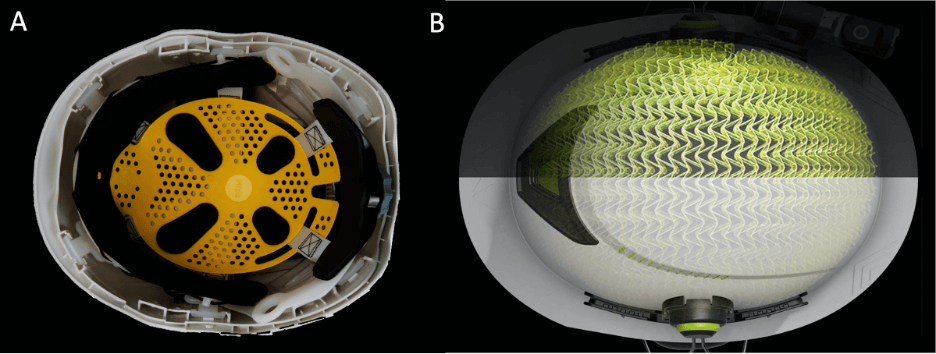

Sports helmets have recently adopted technologies to shield the brain from rotational force. One technology, called MIPS, is a plastic sheet that seeks to reduce transmission of rotational force by slipping during impact (Figure 2A). These MIPS slip liners can be retrofitted into existing helmet designs and are available in a range of bike and snow helmets. In contrast to this 2-dimensional slip sheet, WaveCel technology employs a dome formed of a cellular structure that was specifically designed to fold, crush, and glide during impact (Figure 2B). Compared to standard helmets, it has shown to reduce transmission of rotational forces by up to 57% and was able to reduce the predicted risk of sustaining a concussion by up to 73 – 98%.[8] These rotation-damping technologies have most recently been introduced in safety helmets to better protection from rotational forces than modern safety helmets with an EPS foam core.[3] Since over 50,000 work-related brain injuries are admitted to hospitals in the US each year,[9] selecting helmets that have rotation-damping technology should be a primary consideration when selecting a new helmet.

Figure 2: Rotation mitigation technologies. A) MIPS slip liner; B) WaveCel dome.

CONCLUSION

When choosing a helmet based on available evidence of performance, the following three aspects should be considered:

- Choose a helmet that is ANSI Type II rated to provide protection from lateral impacts which occur far more frequent than crown impacts.

- Choose a helmet with chin straps to ensure the helmet remains on the head during impact.

- Choose a helmet with a rotation-mitigating technology to reduce the risk of brain injury.

In addition to these impact performance criteria, factors pertaining to user satisfaction are equally important for helmet adoption, such as comfort, weight, heat and style. In regard to style, helmets should be selected based on performance, independent of a particular helmet style.

ABOUT THE AUTHOR

Michael Bottlang is the founder and director of the Legacy Biomechanics Laboratory in Portland, Oregon. His research has been funded by the National Institute of Health and he has published over 80 peer-reviewed papers. Dr. Bottlang is also a founder of WaveCel LLC, a helmet company dedicated to reduce the incidence and severity of brain injury.

Corresponding author address:

Biomechanics Laboratory

Legacy Research Institute, 1225 NE 2nd Ave, Portland, OR 97232

Email: [email protected]

Phone: (503) 413 5457

REFERENCES

- Graff HJ, Siersma V, Moller A, Kragstrup J, Andersen LL, Egerod I, et al. Labour market attachment after mild traumatic brain injury: nationwide cohort study with 5-year register follow-up in Denmark. BMJ Open 2019; 9(4):e026104.

- Gilchrist A, Mills NJ. Construction Site Workers Helmets. Journal of Occupational Accidents 1987; 9:199-211.

- Bottlang M, Hodgdon M, Tsai S, Madey S. Climbing style safety helmets do not improve impact protection over type II hard hats. Safety Science 2023; 168(106296):1-7.

- Munoz-Sanchez MA, Murillo-Cabezas F, Cayuela-Dominguez A, Rincon-Ferrari MD, Amaya-Villar R, Leon-Carrion J. Skull fracture, with or without clinical signs, in mTBI is an independent risk marker for neurosurgically relevant intracranial lesion: a cohort study. Brain Inj 2009; 23(1):39-44.

- Gennarelli TA. Mechanisms of brain injury. J Emerg Med 1993; 11 Suppl 1:5-11.

- Fu TS, Jing R, McFaull SR, Cusimano MD. Health & Economic Burden of Traumatic Brain Injury in the Emergency Department. Can J Neurol Sci 2016; 43(2):238-247.

- OSHA. Severe Injury Reports. Occupational Safety and Health Administration 2021; US Deparment of Labor.

- Bliven E, Rouhier A, Tsai S, Willinger R, Bourdet N, Deck C, et al. Evaluation of a novel bicycle helmet concept in oblique impact testing. Accid Anal Prev 2019; 124:58-65.

- Tiesman HM, Konda S, Bell JL. The epidemiology of fatal occupational traumatic brain injury in the U.S. Am J Prev Med 2011; 41(1):61-67.